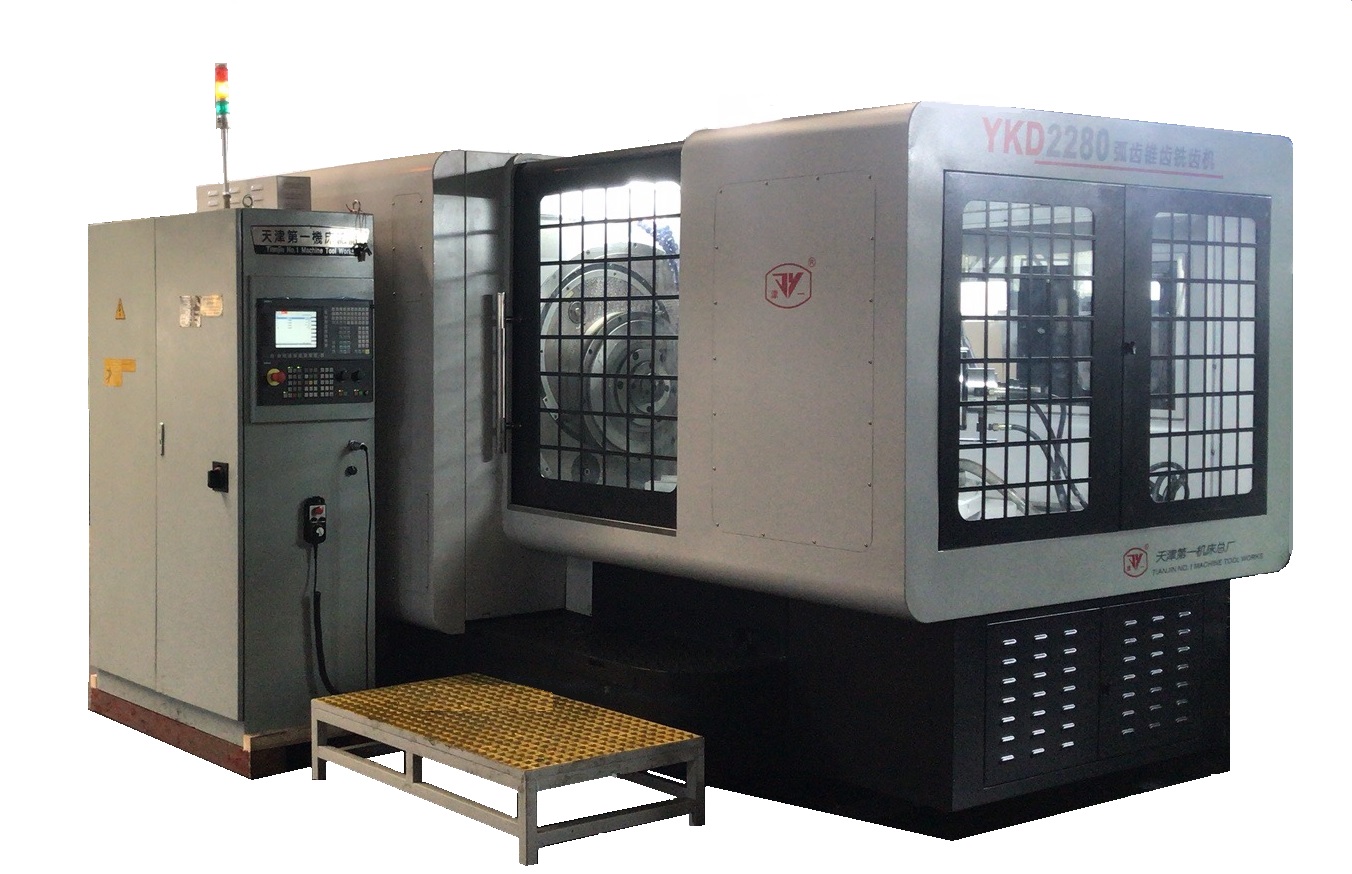

YKD2280 CNC Spiral Bevel Gear Generator

YKD2280 CNC SPIRAL BEVEL GEAR GENERATOR

Ⅰ. Applications of Machine

Model YKD2280 machine is a precision CNC Spiral Bevel Gear Generator, which is designed for roughing and finishing Spiral Bevel Gears and Hypoid Gears and Equidepth gears of the Gleason system with the diameter up to 800mm and module 15mm.

On this machine, the cutter is mounted on the cradle (circular guideway). The integral structure is rigid, highly accurate and working stably. The cradle-type gear cutting machine, which is also possible for hard surfacing, is durable and the service life will be several dozens of years under normal operating conditions.

The machine is with universal features and it is suitable for roughing and finishing, in mass production, gears used for medium & heavy load trucks, mining machineries, construction machineries and shipbuilding industry.

The machine is equipped with a CNC control system 828D (SIEMENS) and designed to operate as a three-axis machine, i.e. cradle rotation (X axis), work spindle rotation (Y axis) and sliding base movement (Z axis) being simultaneously controlled by the CNC control system to cut gears. The rotation of cutter spindle (S axis) is controlled by an A.C. frequency-variable motor for its stepless control. Therefore, no change gears will be used on the machine for cutting gears. The machine operation is easy and flexible. The clients who have the conventional machines can convert the machine settings used for YT2250 (or Y225) and Y2280 machines into the machine settings for the YKD2280 machine.

Ⅱ. Main Features of Machine

An A.C. frequency-variable motor is used as a main driving power source while the cradle rotation and work spindle rotation are driven by the servo motors. The sliding base movement is driven by a servo motor through a ball screw. All of these features of the machine are for the purpose of simplifying the conventional mechanical structure, reducing the machine setup time and shortening the transmission train because of the change gears elimination. In this case, not only the machine accuracy is increased, but also the operation is easy and convenient. Safety guards and an automatical chip conveyor may be provided on the machine. The machine is equipped with a sealed electrical cabinet which is with an air conditioner.

Ⅲ. Power Supply: 380V, 50 HZ

Ⅳ. Main Electrical Parameters:

A.C. Frequency-variable Motor (main drive) 15KW, 1500rpm

Servo Motors (cradle & workhead) 42NM, 1500rpm

Servo Motor (sliding base movement) 23NM, 2000rpm

Total Power Capacity 35KVA

Ⅴ.Specification of Machine

被加工工件的尺寸 Dimensions of work to be cut | ||||||||

最大加工模數(shù) Max. module | 15 | mm | ||||||

最大節(jié)錐母線長 Max. pitch cone distance |

螺旋角 Spiral angle | 0° | 285 | mm | ||||

15° | 350 | mm | ||||||

30° | 350 | mm | ||||||

工件的節(jié)錐角 Pitch angle of workpiece | 最大 Max. | 90° | ||||||

最小Min. | 5° | |||||||

被磨齒輪副軸間角為90°的最大傳動比 Max. gear ratio (shaft angle 90°) | 10:1 | |||||||

被加工齒輪的 最大節(jié)圓直徑

Max. pitch diameter |

被加工齒輪副 傳動比

Gear ratio |

10:1 |

螺旋角

Spiral angle | 0° | 575 | mm | ||

15° | 700 | mm | ||||||

30° | 800 | mm | ||||||

2:1 | 0° | 520 | mm | |||||

15° | 635 | mm | ||||||

30° | 750 | mm | ||||||

1:1 | 0° | 395 | mm | |||||

15° | 500 | mm | ||||||

30° | 600 | mm | ||||||

最大齒寬 Max. face width | 100 | mm | ||||||

螺旋角 Spiral angle | 0°~60° | |||||||

最大齒高 Max. tooth depth | 32 | mm | ||||||

齒數(shù) Number of teeth | 4~100 | |||||||

砂輪直徑 Diameter of Grinding wheel | 6″9″12″18″ | |||||||

工 件 箱 workhead | ||||||||

從主軸端面至機床中心的距離 Distance from face of spindle to machine center | 最大Max. | 600 | mm | |||||

最小Min. | 125 | mm | ||||||

表示主軸端面至機床中心距離游標(biāo)尺每一格的讀數(shù)Reading of each graduation for Vernier & scale showing the Distance | 直尺 Scale | 1 | mm | |||||

游標(biāo)Vernier | 0.02 | mm | ||||||

主軸從中心位置的向下垂直移動Downward from center position | 當(dāng)主軸端面至機床中心調(diào)整位置為右列各值時when the distance from face of spindle to machine center being at | 125~270 | 25 | mm | ||||

270~330 | 70 | mm | ||||||

330~540 | 90 | mm | ||||||

主軸從中心位置的向上垂直移動 Upword from center position | 90 | mm | ||||||

主軸垂直移動游標(biāo)尺每格讀數(shù)Reading of each graduation for Vernier & scale showing the upward and Downward | 直尺 Scale | 1 | mm | |||||

游標(biāo)Vernier | 0.02 | mm | ||||||

主軸錐孔尺寸 Taper hole of spindle | 大端直徑at large end | 153 | mm | |||||

錐度Taper | 1:20 | |||||||

錐長Length of taper | 180 | mm | ||||||

主軸通孔直徑 Diameter of through hole | 125 | mm | ||||||

主軸發(fā)藍(lán)直徑 Colouring diameter of spindle | 235 | mm | ||||||

搖 臺 Cradle | ||||||||

搖臺安裝角 Setting angle | 最大Max. | 360° | ||||||

最小Min. | 0° | |||||||

搖臺安裝角每一刻線值Reading of each graduation for vernier & Scale showing setting angle | 圓周上Scale | 30′ | ||||||

游標(biāo)上Vernier | 1′ | |||||||

搖臺偏心調(diào)整角 Eccentric setting angle | 最大Max. | 180° | ||||||

最小Min. | 0° | |||||||

砂輪主軸的相應(yīng)徑向位移 Radial setting of wheel spindle | 最大Max. | 340 | mm | |||||

最小Min. | 0 | mm | ||||||

偏心量調(diào)整角每一刻線位 Reading of each graduation for Vernier & Scale showing eccentric setting angle | 圓周上Scale | 20′ | ||||||

游標(biāo)上Vernier | 1′ | |||||||

搖臺最大擺角Max. cradle oscillating angle | 60° | |||||||

床 鞍 Sliding Base | ||||||||

由中心位置移動最大距離 Max. movement from machine center | 向前Forward | 25 | mm | |||||

向后Backward | 150 | mm | ||||||

其 它 Miscellaneous | ||||||||

機床外形尺寸(長×寬×高) Overall dimensions of machine | 2900×2750×2200 | mm | ||||||

機床凈重 Net weight of machine | 12.5 | T | ||||||