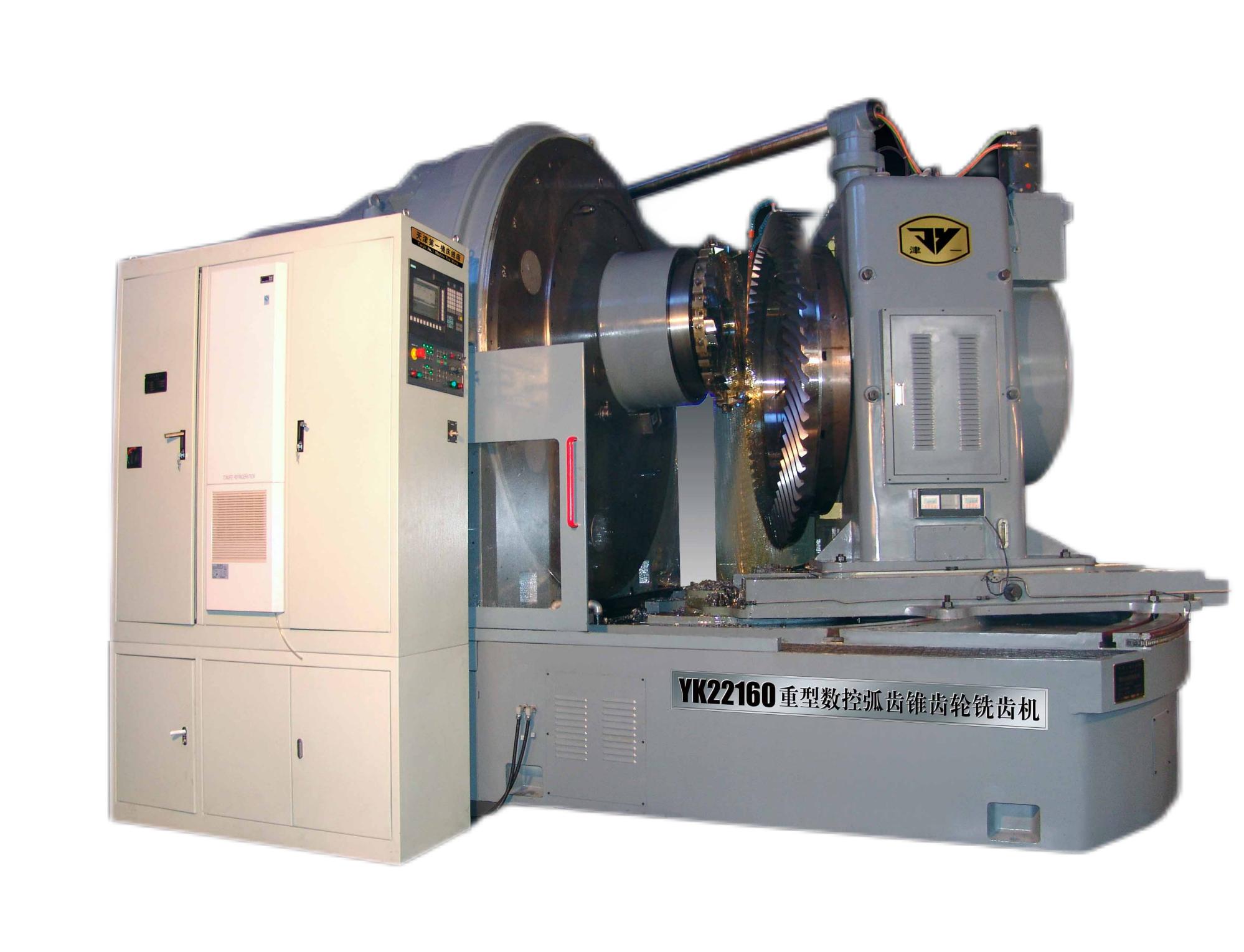

YK22160 CNC Spiral Bevel Gear Generator

YK22160 CNC SPIRAL BEVEL GEAR GENERATOR

Ⅰ. Applications and Features of the Machine

This machine is a heavy-duty machine tool designed to cut spiral bevel gears, zero bevel gears, hypoid gears and constant-depth tooth bevel gears of diameter up to 1600mm and module up to 30mm. The machine is especially suitable for the machining of large spiral bevel gears used in mining, petroleum, metallurgical, ship building, wind power, cement and dock machinery industries.

The accuracy of the workpieces machined on this machine can reach Grade 8 of GB Standard, and can reach Grade 7 after careful fine adjustments of the machine.

Ⅱ. Main Performance and Structural Characteristics of the Machine

1. This machine is a three-axis CNC spiral bevel gear generator (A SIEMENS 828DSL CNC control system is equipped). The three CNC controlled movements are the cradle movement (X-axis), the work spindle movements (Y-axis) and the feed of the cutter spindle (Z-axis).

The rotations of the cutter spindle (S-axis) are controlled by means of the frequency- variable speed regulation and 18″~40″ cutters can be used on this machine. Because of the great variation of the cutter diameters, in order to avoid the power loss owing to the wide speed variation, three kinds of change gears are available.

2. High precision worm and worm wheel pairs are mounted for both the cradle and the workhead to insure the accuracies of indexing and generating roll.

3. A hydraulic floating device is mounted on the sliding guideway surface to reduce the moving force created when adjusting the machine.

4. Fine quality CNC system, electrical and hydraulic components, bearings and sealing parts provided by the CE certified suppliers are adopted on the machine to guarantee the reliability of the machine.

5. The hydraulic oil used for the machine is thermo controlled.

6. An enclosure and an automatic chip conveyor are equipped on the machine.

7. This machine has a better rigidity. The cradle lock and the overhead tie bar form the machine to an integral frame structure. The machine is capable for hard surfacing.

Ⅲ. Specifications

1. Work to be Machined | ||

Max. outer cone distance (30°spiral and &40"cutter) | mm | 1610 |

Extreme ratio | 10:1 | |

Max. pitch diameter (30°spiral angle) | ||

Ratio 10:1 | mm | 1610 |

Ratio 2:1 | mm | 1445 |

Ratio 1:1 | mm | 1145 |

Max. module | mm | 30 |

Max. cutting depth | mm | 70 |

Max. face width | mm | 240 |

Max. radial setting | mm | 620 |

Spiral angle | 0°~ 45° | |

Teeth number | 4~100 | |

2. Work Spindle | ||

Diameter of taper hole at large end | mm | 300 |

Taper | 1:20 | |

Diameter of through hole | mm | 245 |

Diameter of flange | mm | 510 |

Diameter of face plate | mm | 1600 |

3. Cutter Spindle | ||

Speed of cutter | rpm | 10~37 |

Diameter of cutter | mm | 18"~ 40" |

4. Workhead Setup | ||

Max. offset of work spindle | mm | 120 |

Machine center to nose of spindle | mm | 200~1150 |

5.Miscellaneous | ||

Power of main motor | kw | 22 |

Total power of the machine | kw | 34 |

Overall Dimensions (L×W×H) | mm | 5800×4492×3900 |

Net Weight | kg | 95000 |