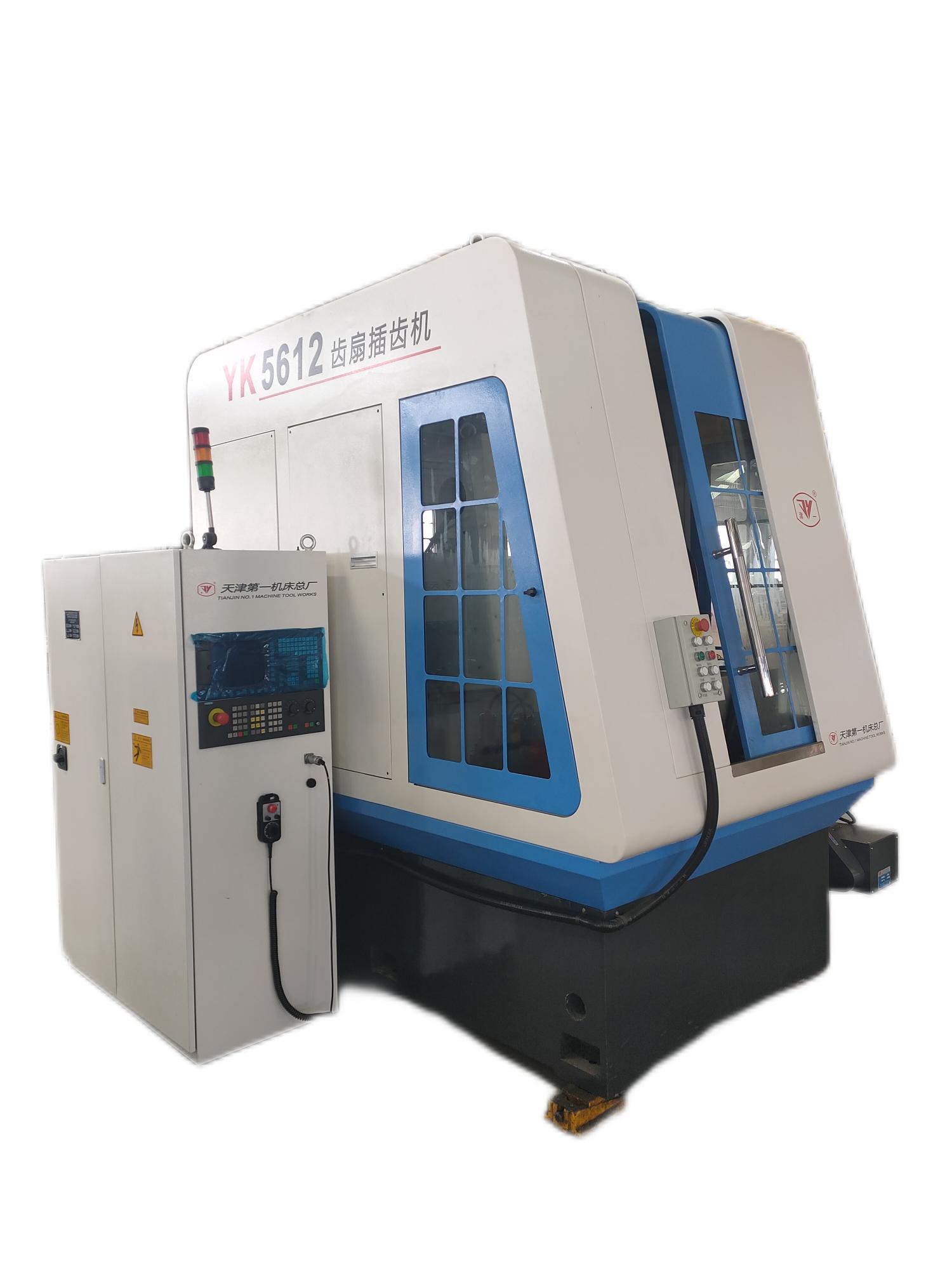

YK5612 CNC Steering Sector Gear Shaper

YK5612 CNC STEERING SECTOR GEAR SHAPER

Ⅰ.Machine Applications

This machine is a CNC steering sector gear shaper with the radial feed conducted by the column.

This machine is designed for the steering sector manufacturers of the automobile industry for the production of the segment gears with constant ratio, variable ratio or crowned tooth profiles on the steering shafts. It’s most suitable for the mass production.

Ⅱ.Machine Performances and Structural Characteristics of Machine

1. The machine is a longitudinal layout. The structures and transmission rigidity of the machine bed, column, saddle and the working surfaces are excellent to ensure the high machining accuracy, high reliability and low noise level.

2. This is a CNC steering sector gear shaper with three CNC controlled axes, equipped with a SIEMENS CNC control system and a servo system to perform the control of the worktable rotation, the tangential feed of worktable and the radial feed of column.

3. The main movement of the machine adopts a high-rigidity slide reciprocating structure controlled by the stepless speed regulating device of the frequency-variable motor. The stroke numbers of the slide per minute can be controlled through program of the CNC system, and an automatic changeover is possible. A comb-type cutter is used on the machine.

4. The machine adopts an optimized-curve double-roller cam cutter relieving mechanism to ensure the precise, stable and low noise cutter relieving motion.

5. A high-precision variable tooth thickness worm and worm wheel pair is equipped on the machine.

6. The machine adopts a column tilt mechanism to ensure the rigid taper gear cutting operations.

7. High performance and high reliability functional components (the CNC system, the linear rolling guideways, ball screws, etc. ) of the famous brands at home and abroad are adopted to guarantee the high reliability and keep the accuracy of the machine.

8. Forced lubrication will be applied for the reciprocating movement of the slide, and timed and quantitative lubrication will be applied for the worktable.

9. A coolant system of a great flowrate is used on the machine in order to ensure the stability of the machine accuracy and the long service life of the cutter.

10. An independent hydraulic pump station with safe sealing is equipped for the machine, and an electrical control cabinet with an air conditioner may be available.

11. A beautiful, safe and suitable full-enclosure may be equipped on the machine, which is of good visibility, convenient operation and easy maintenance.

Ⅲ.Machine Specifications

Maximum diameter of work | mm | 120 |

Maximum module of work | mm | 12 |

Maximum face width | mm | 80 |

Maximum stroke length of cutter | mm | 90 |

Tilt angle of column | 0~8°(10°is possible) | |

Number of cutter strokes(stepless) | str./min. | 90~600 |

Diameter of worktable | mm | 300 |

Maximum tangential travel | mm | 230 |

Maximum radial travel | mm | 120 |

Speed of tangential feed(X-axis, stepless) | mm/min. | 0~3000 |

Speed of radial feed(Z-axis, stepless) | mm/min. | 0~3000 |

Worktable rotation(Y-axis, stepless) | rpm | 0~6 |

Power of main motor | kw | 11 |

Total power of machine | kw | 25 |

Overall dimensions(L×W×H) | mm | 2850×1900×2550 |

Net weight | kg | 11000 |